Hello and welcome to the baling world! For those new to the industry, it’s important to understand the proper use of poly strapping tools to ensure the safe and efficient handling of bales.

At Vulcan Wire, we specialize in providing high-quality products and expert advice to help you succeed in your baling endeavors.

This guide will cover the fundamentals of using poly strapping tools, including the different types available, their specific uses, and best practices for achieving optimal results.

Types of Poly Strapping Tools

Poly-strapping tools are crucial for securing and tightening polypropylene or polyester straps around bales and other packaged goods. Three primary types of tools are utilized in the baling industry:

- Manual Strapping Tools

- Battery-Powered Strapping Tools

- Pneumatic Strapping Tools

Each type of tool has its advantages and specific applications, so it’s crucial to choose the most suitable tool to meet your requirements.

[Buy Poly Strapping Tools Today]

Let’s delve into each type and its specific uses.

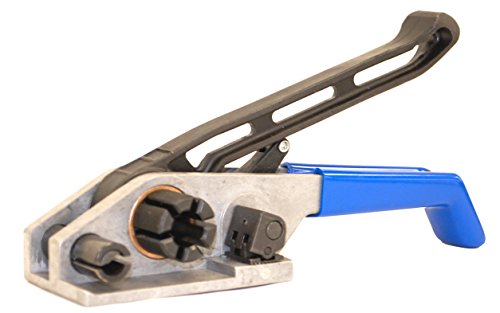

Manual Strapping Tools

If you’re new to the baling industry, manual strapping tools are an economical and trustworthy option. They are perfect for low-volume applications or situations where there is no access to electricity. Generally, manual tools are comprised of tensioners, sealers, and cutters.

- Tensioners: These tools assist in tightening the strap around the bale and ensuring a snug fit. To use a tensioner, thread the strap through the tool, turn the handle to create tension, and then secure the strap with a seal or buckle.

- Sealers: Sealers are employed to apply seals or buckles to the strap, securing it in place. To use a sealer, insert the strap’s ends into the tool and compress the handles together, crimping the seal or buckle onto the strap.

- Cutters: Lastly, cutters are pivotal in cutting excess strap material after securing the bale. Glide the cutter along the strap, and apply pressure to make a clean cut.

Battery-Powered Strapping Tools

For those seeking enhanced efficiency and speed compared to manual options, battery-powered tools are an excellent choice. They are ideal for medium to high-volume baling applications, saving time and effort.

Battery-powered strapping tools are an all-in-one device that combines tensioning, sealing, and cutting. Using these tools is simple – insert the strap into the tool and press the trigger. The tool automatically tensions, seals, and cuts the strap in a quick and straightforward manner.

Pneumatic Strapping Tools

Pneumatic tools are energized by compressed air and recommended for high-volume baling applications or situations that call for the foremost speed and efficiency. Similar to battery-powered tools, pneumatic strapping tools integrate tensioning, sealing, and cutting in a single device.

To use a pneumatic tool, fasten it to an air compressor, and thread the strap into the tool. Press the trigger, and the tool will automatically tension, seal, and cut the strap. Pneumatic tools are recognized for their rapidity and sturdiness, establishing them a desirable choice for extensive operations.

Best Practices for Using Poly Strapping Tools

Now that you’re familiar with the various poly strapping tools, let’s go through some effective and safe practices.

- Choose the best type of strap: It’s essential to select the adequate strap material (polypropylene or polyester) and width to ensure successful baling. Consult with a strapping expert at Vulcan Wire or refer to the manufacturer’s guidelines to guarantee you’re using the proper strap for your application.

- Inspect your tools: Regularly examine your strapping tools for any signs of wear or damage. Damaged tools can result in inadequate performance and safety risks. Replace worn or damaged parts as needed and adhere to the manufacturer’s maintenance instructions.

- Ensure suitable tension: Applying the correct tension to your straps is crucial for safe and secure baling. Excess tension can damage your bales, and insufficient tension may cause them to come undone. Follow the manufacturer’s recommended tensioning and adjust it as needed for your specific application.

- Utilize appropriate seals or buckles: Choose the appropriate type of seal or buckle compatible with your strapping material and tool. Using incompatible components results in a weak connection and potential bale failure. Review the manufacturer’s guidelines before selecting seals or buckles.

- Wear safety gear: Strapping tools can be hazardous if not used correctly. Always safeguard yourself using suitable personal protective equipment (PPE), including safety glasses, gloves, and closed-toe shoes.

- Train your team: Equipping all team members with proper training is crucial for proficient baling and workplace safety. Regularly review and reinforce the best practices with your team to maintain a high level of expertise.

- Keep your work area clean: A clean and organized workspace facilitates efficiency and reduces the risk of accidents. Regularly eliminate debris, excess strapping material, or other obstacles to maintain a safe work environment.

Conclusion

As a newcomer to the baling industry, understanding the proper use of poly strapping tools is key to success. By familiarizing yourself with the different types of tools, their specific uses, and following best practices, you can ensure the safe and efficient handling of your bales.

At Vulcan Wire, we are committed to providing top-quality products and expert guidance to help you excel in your baling endeavors. With the right tools and techniques, you’ll be well on your way to becoming a baling pro in no time.

Our poly strapping tools are designed for long-lasting performance and reliability, making them an ideal solution for your baling needs. Contact us today for more help.